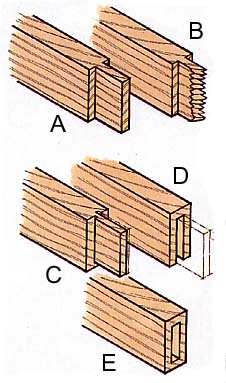

Various plaintive requests for remedies to under-sized tenons are a fairly common feature. Possibly the worker has sawn the wrong side of the gauge line and the tenon is now too thin. Another problem arises where the shoulder has been sawn too deeply and undermined the tenon.

Splines probably offer the only secure remedy for these blunders, (illustrated (not very clearly) at 'C').Frequently one sees suggestions that if you stick a bit of veneer on a tenon face, all will be well. The snag is that while the joint will fit and now adequately take the glue, there is no longitudinal continuity of the grain fibres. The botched, though hidden, tenon will still be weaker at its root.For joint 'D', form as much as possible of the slot's flanks by first sawing diagonally with a tenon saw. Chop the remaining waste as you would when morticing. Alternatively you could rout out the slot. A 'G' or similar cramp will be needed to apply pressure across the slot while gluing the spline in place.

For version 'E', remove most of the waste by drilling. When paring to trim the remaining material in short-grained wood, remember that while working one flank you will be working against the grain. Light cuts with a very sharp chisel will be essential.

Mortising into end-grain can be difficult, so adopt the semi-concealed version 'D' whenever the underside is not normally visible.

Version 'D' can also be extremely useful in repairing old work since broken tenons can be extracted from their mortises and replaced with some glued-in splines onto which the old rail can drop.

Splines can be produced in bulk, of course, and if necessary can be of a stronger wood.

Some workers design with splined tenons as standard practice. Rail ends can be planed or sanded square. You get perfectly-fitting shoulders with little effort.