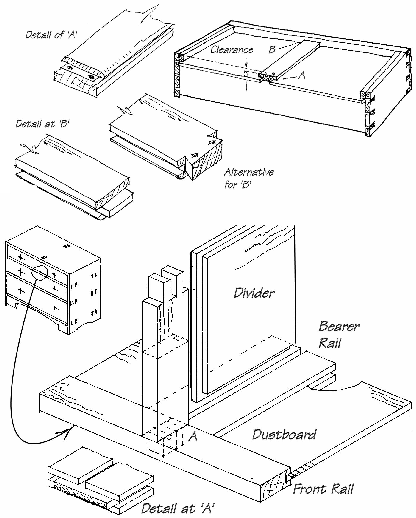

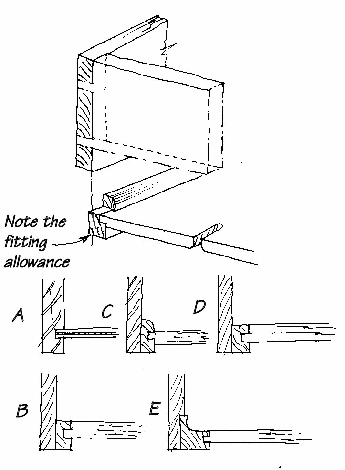

The lap (half-blind) dovetails are formed on drawer fronts whose top edges are slightly off-square. The ends are similarly planed.

This creates a tapered front (in effect a truncated rectangular prism) that will just enter the opening to a depth of a couple of millimeters or so.

The back is dimensioned so that it will just fit inside the opening.

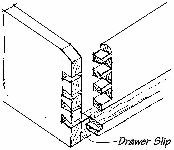

Note the use of glued-in slips that increase the bearing area of the sides (detailed below).

The remote ends of the sides are shown chamfered to ease entry of the drawer, although some people credibly argue that if the lower edges were to be chamfered, the drawer would have slightly less droop when nearly fully opened

The crafty cabinetmaker sets out his carcase dovetails (or whatever) so that the cabinet is very slightly wider at the back). To have the converse is to be unable to effectively fit the perfect drawer that gets slightly tighter as it is pulled out)

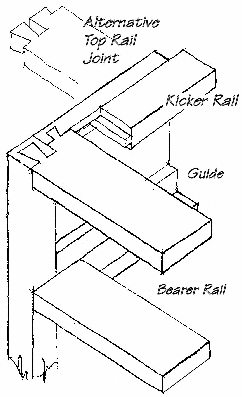

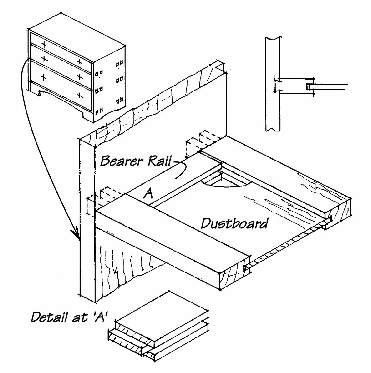

When setting out the rail mortises, ensure that twist is not induced into the system.

It would be better for the bearer rails (that are also kicker rails for the drawers below) to be very slightly concave in length rather than convex.

The small drawing shows an end view of the alternative tapered dovetail housing (sliding dovetail).

At the time of assembly, the more stable are the frame members, the better. A small amount of distortion can make a great difference to drawer fitting.