A close-up of a marking knife cut. For the sake of the size of an extreme close-up, this was cut in a soft hardwood (Jelutong).

Note how the left-hand side of the cut is at right-angles to the face of the wood. Close inspection will show that the fibres on the upper corner are slightly deformed downwards.

Although it is not very evident, the right-hand fibres are considerably crushed and bent downwards.

In a moderately hard wood the line width could be about 0.4mm (15thou) and the depth 0.8mm (30thou).

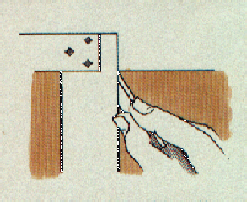

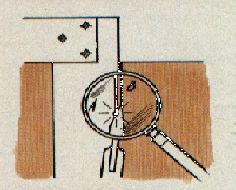

To make the photo, the knife was held as shown. Note how the bevel (on the left-hand side of the blade) is (approximately!) vertical to the surface of the workpiece.

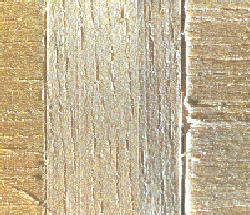

The two sides of the same cross-halvng joint, also in Jelutong. (Two prints were necessary at this magnification, hence the slight difference in colour). Although the joint was a perfect fit, this is not apparent when you look at its right-hand side.Each knife line was struck with the try square and knife position as above. This meant that the crushed side of the left-hand line was in the waste.

Does it really matter? The gap will go when the surface is cleaned up, won't it? Even with a fairly large 1.5thou set on a smoothing plane, twenty strokes would (in theory at least) be needed to remove this depth of surface.

Of course, there is a chance that the crushed fibres will swell back when the joint absorbes moisture from the glue, but it would have been better to have turned the square over and rotated the job so that the crushed side of the line was in the waste.

It would, of course, be possible simply to alter the angle of the marking knife so that its right-hand side becomes vertical. The actual point of contact is starred. However, the knife point is no longer tucked firmly against the square. If the worker's hand were to tilt to the right as he/she pulls, the line could easily go adrift. Since the wrist and arm positions are now uncomfortable this is quite possible.