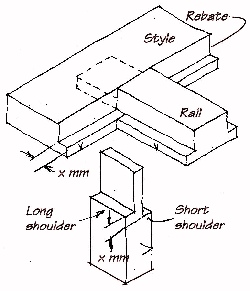

Whereas powered routers can form rebates (rabbets) by running round the edges of an assembled frame, rebates formed with hand planes need to run from end to end of the workpiece.

To fill the gap that would appear if the tenon had equal shoulders, one is made 'longer', ie to project further, than the other.

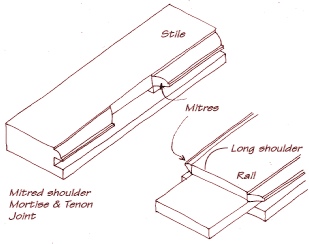

Mitred long and short shoulders are required where hand-made mouldings need to be 'returned' round a joint.

This is a hand-cabinetmaker's technique.

Users of powered routers and spindle moulders can undercut (ie 'scribe') the shoulder to match the moulding.