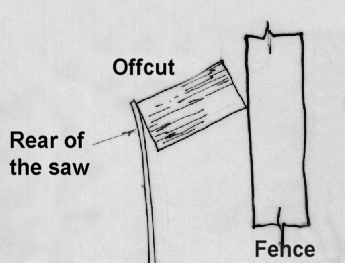

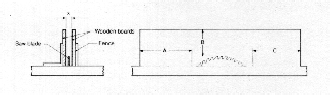

The right-hand diagram illustrates what can happen when a short offcut is trapped between the uprunning teeth and the fence. As the end is caught by the teeth, the offcut rotates. It deflects the blade until it is violently catapulted towards the sawyer.

It is worth noting that if the guard were to be in place, the chances of the offcut hitting the sawyer's face should be considerably reduced.

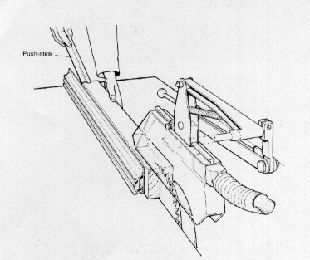

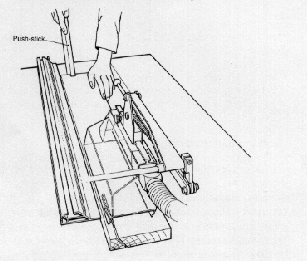

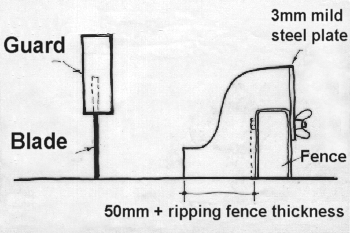

For operations such as grooving, panel raising and so on, consult the Figure 8 and 9 of the HSE information sheet for general design details of a suitable guard/fence.HSE Information Sheet.

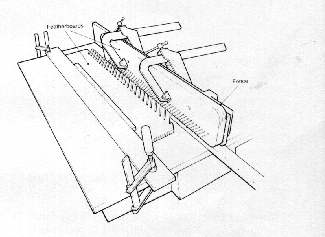

Given some assistance with taking off, this small section stuff is adequately guarded.

Since feeding becomes difficult, it does illustrate however, the difficulty of effectively guarding short sections.

Apart from the evidently unfinished drawings, the illustrations are taken from the British Health and Safety Executive's Information Sheet 16.