Bored with woodworking? Then try one of these…

It is probably preferable to make the tails first, just as you would do for a common through dovetail joint.

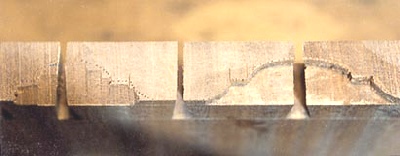

Scribe and saw the pins more or less in the usual way. Note that some cuts should be shorter than others, ie they do not reach the shoulder line of the tail socket floors.

Make the tail sockets just like an ordinary lapped (blind) dovetail.

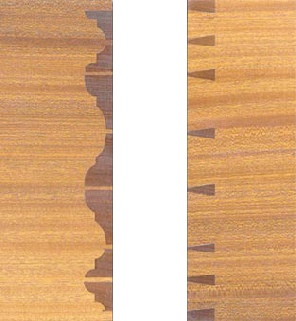

Prepare a template for the curved shape. It must have a baseline indicating the location of the tail socket floors. Precisely locate the template and scribe the shaped lap from the template. Use a jeweller's saw to rough out the curve. Since using a chisel would be rather tricky, finish with fine files, taking care not to fray the edges. This profile must exactly match the template. If you go a bit too far, alter the template to match your curve.

Offer the pin bearer to the socket bearer in the usual way and cut the sockets.

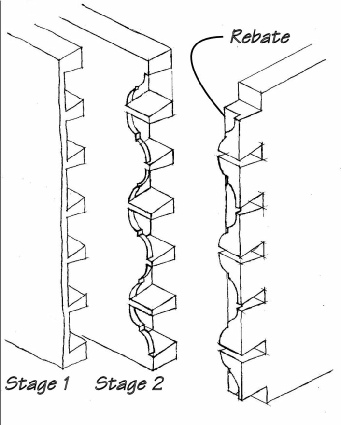

Note that at this stage the design allows the pins to just enter their sockets. Assemble the joint as well as you presently can.

Using a magnifier, locate the template absolutely dead above the face side of the tail bearer and with a sharp awl prick out the curve.

Pare the end-grain rebates to match the awl marks.