The most common form of donkey's ear shooting board has the fence fixed at the far end of the board (Left)… If you have followedFace Side and Face Edge Marksyou will know that good practice involves the face edge of the workpiece always resting against the fence. With this arrangement, only one end of, say, a box side, can be mitred with its face edge against this kind of fence.

(All the same, generations of craftsmen who make their jobs with truly parallel sides have successfully managed to get good results).

To enable the datum edge always to rest against the fence, the fence needs to be positioned mid-ships along the baseboard.

The plane can then either be pushed…

…and the wood turned end to end; placed the other side of the fence and the plane is pulled. It is not half as difficult as it might appear.

These photos illustrate what happened when I re-designed my old shooting board.

Over the years, the baseboard had deformed somewhat, so it had to be planed true and out of wind (ie not twisted).

Using a sliding bevel set to 45°, both the angle and flatness of the running board were checked with a pair of inside calipers.

For the jack plane to be able to true this surface, the dust groove must be wider than the lateral margin of the plane. There's no point in pretending that this planing job is other than a bit tricky.

The lateral margin is the strip running along the length of the plane whose width is equal to the distance between the cutting edge and the flank of the plane.

If you have followed the description of the common shooting boardA Versatile Shooting Boardyou will know that the sole of the plane should bear against the end of the fence. If this is the case, it doesn't matter unduly if the flank of the plane is not quite square to the sole.

Most of the pressure should be sideways. The top of the fence should be level with the flank of the plane.

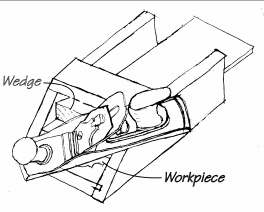

The traditional pattern of fence is fitted into a tapered dovetail housing (see the top picture). If the fence shrinks, as it will over time, it can easily be tightened with a thump on its rear.

However, a tapered fence would be wrong for the midships fence, so it has to be bolted in place.

One snag with the above pattern is that it can be difficult to hold long and heavy workpieces in place. They tend to slide down and are hard to hold against the fence.

There exists designs of shooting board in which the baseboard is inclined at 90deg to that illustrated. The idea is that the weight of the workpiece acts towards the plane instead of away from it. I haven't got one, and haven't tried one.

An alternative for wide and long boards (eg cabinet plinths) is illustrated on the left.

You can also make mitre blocks that incorporate a cramping screw.