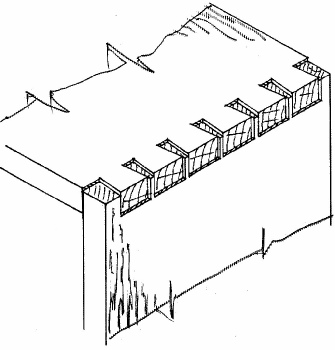

If you have seen the text inA Bookcase in Oakyou will have noticed that pins and tails can be made so that,until the surface of the job is planed during 'cleaning up', they lie recessed slightly beneath the surface, as also illustrated below.

In this case the un-labelled dimension can be 1 mm (1/32) less than the thickness of the mating part.

Otherwise, the dimension indicated in the drawing can be made 2 (3/32 in) mm greater than the thickness of the mating part, thus allowing the pins and tail ends to project. This is the easier way if you are not yet hot at dovetailing.

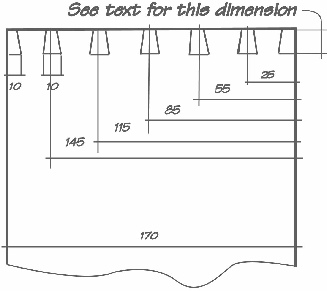

It is usual for the pin spacing to be made closer towards the sides of a carcase. This is a precaution against the panels warping over a period of time.

I've shown fairly clumsy pins. For fine work they can be made somewhat narrower.

Don't make them too narrow or you will find that starting the saw will be very tricky. Also, if they are made too flimsy and the job turns out too tight, they can be ripped from their sockets when the job is knocked apart.