Please note:This is intended to be a technique suitable for plane soles, for the average worker with limited facilities. I'm afraid that perfectionists will need to look elsewhere.

After checking the abraded sole on a blued-up surface plate, you might be surprised to find that, although it might be better than it was, the contact is still not as complete as you wish. It might be quite adequate for many purposes. If you decide you want to go further, removing minute amounts by finishing with an engineer's scraper to can generate a fairly accurate surface. In my view, it gives an impressive finish. It is not at all difficult for anyone who can handle a wood chisel, but you do need some patience.

Ideally an engineer's cast iron or granite surface plate is best, but instead you can manage with a glass plate to act as a surface plate.

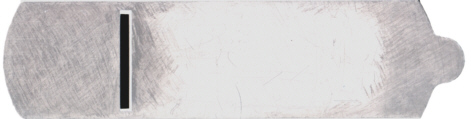

A shop-made engineer's scraper.

You'll also need some engineer's blue, but not marking out paint which is also blue. SeeScraping Practicalities.

Scraping involves holding the scraper at a fairly low angle to the surface and raising the handle until the edge scrapes. You will soon get the feel of it. Starting at one end, lightly jab diagonally on each high spot using short strokes. You will produce a fine powder, part metal, part graphite. Do not hold the scraper at too high an angle. Keep the scraper in contact with the metal during the back stroke, but release the pressure.

Re-blue. Resharpen the scraper and work at right-angles to the old strokes. As you proceed, a regular series of small contact spots will develop. When the spots are about 6mm (1/4 inch) or less apart, the surface will be as good as the system can make it. Concentrate on leaving a line of high spots just in front of the mouth by avoiding this area until the job is nearly complete.

The photo is of the sole of the half-completed, scraped surface of a Record SP4 plane. The area forward of the mouth is dead flat and some of the area behind is not yet scraped (and could easily be left alone). However, if the sole happened to be convex, you'd have to scrape the entire area.

This economy plane, from a maker of good quality mass-production planes, lacks some frills, but they do not affect working quality. Although there is no frog adjusting screw, the shaving aperture can still be adjusted, so the SP4 and similar planes can be fine-tuned to give as good a finish as the more expensive planes.

The black area is actually a reflection of the grinding bevel of the blade. The (almost invisible) shaving aperture is about 3thou wide.

It originally had a bump just behind the mouth.